In the world of technological advancements, 4D printing emerges as a fascinating concept that sparks curiosity and intrigue among researchers, engineers, and dreamers alike.

|

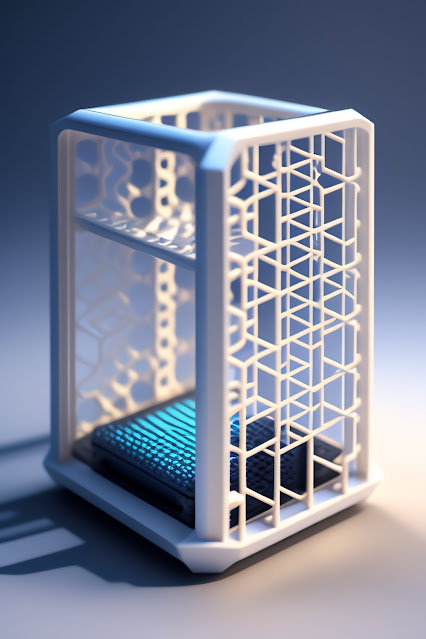

| A mesmerizing 4D-printed object showcasing its self-adapting properties, illustrating the revolutionary potential of 4D printing technology. |

SYNOPSIS:

This humble article introduces readers to the revolutionary world of 4D printing, where materials possess the ability to adapt and transform over time. Beginning with an exploration of the origins of 4D printing and its evolution from traditional 3D printing, the article unveils the scientific principles and mechanisms behind this cutting-edge technology. Through diverse examples, the applications of 4D printing in healthcare, construction, aerospace, and robotics come to light, promising groundbreaking possibilities in various sectors. However, with a balanced perspective, the article acknowledges the challenges, such as material limitations and environmental considerations, that must be overcome for 4D printing to reach its full potential. Ultimately, with a sense of humble optimism, the article concludes by envisioning the future of 4D printing, where it stands poised to transform industries and contribute to a dynamic and adaptive future.

Introduction:

|

| A close-up view of shape-memory polymers at work, highlighting their ability to change shape and return to their original form in response to external stimuli. |

In recent years, 3D printing has revolutionized the manufacturing industry, enabling the creation of intricate and customized objects with ease. However, the technology doesn't end there. Enter 4D printing, an innovation that takes 3D printing to a whole new dimension, quite literally. In this article, we'll explore the fascinating world of 4D printing, its potential applications, and why it's considered the future of self-adapting and programmable materials.

What is 4D Printing?

|

| An array of stimuli-responsive materials, such as heat, light, and moisture-responsive substances, demonstrating their role in programmable 4D printing applications. |

4D printing is an advanced manufacturing technique that goes beyond traditional 3D printing by introducing an additional dimension - time. The fourth dimension, time, allows 3D-printed objects to transform, self-assemble, or adapt to environmental stimuli autonomously. This transformative ability is made possible through the use of smart materials or programmable matter.

Smart Materials: The Key to 4D Printing

|

| An overview of the 4D printing process, from the digital blueprint to the dynamic realization, showcasing the intricate steps involved in bringing self-adapting materials to life. |

At the heart of 4D printing lies smart materials, also known as shape-memory materials or self-assembling materials. These materials possess the unique ability to change their shape, structure, or properties in response to external triggers like temperature, humidity, light, or mechanical forces. By integrating such materials into the 3D printing process, engineers and researchers can create objects that can reshape themselves after production.

The 4D Printing Process:

|

| A futuristic architectural marvel created using 4D printing, illustrating how dynamic and adaptive structures are transforming the construction and architectural industries. |

The process of 4D printing starts with the design phase, where engineers use computer-aided design (CAD) software to create the desired structure. Next, the smart materials are carefully chosen and incorporated into the design. These materials are typically polymers with specific molecular arrangements that dictate their responses to stimuli.

During the printing process, layers of the smart material are deposited using various 3D printing techniques like Fused Deposition Modeling (FDM) or Selective Laser Sintering (SLS). Once the object is printed, it undergoes post-processing, during which it is exposed to the triggering stimulus, causing it to transform into the intended shape or configuration.

Applications of 4D Printing:

|

| Step into the future of architecture with dynamic and smart structures built through 4D printing. 🏗️ #SmartStructures #4DArchitecture |

1. Biomedical Devices: 4D printing has immense potential in the medical field. Imagine stents that can change shape to fit blood vessels perfectly or orthopedic implants that adapt to the body's natural movement. These self-adapting medical devices could significantly improve patient outcomes and reduce the need for multiple surgeries.

2. Aerospace and Robotics: Self-adapting structures in aerospace can lead to more efficient aircraft wings that adjust their shape during flight, reducing drag and fuel consumption. In robotics, 4D-printed components can enable robots to change their configurations for various tasks without the need for complex mechanisms.

3. Architecture and Construction: Programmable materials in architecture could lead to self-assembling structures, temporary shelters, or adaptive facades that respond to changing weather conditions, reducing energy consumption and enhancing building resilience.

4. Fashion and Textiles: 4D printing can revolutionize the fashion industry by creating self-transforming garments or accessories that change shape or appearance according to the wearer's preferences or environmental factors.

Challenges and Future Prospects:

|

| 4D bioprinting: revolutionizing medicine with personalized and tissue-engineered solutions. 🏥 #4DBioprinting #MedTech" |

Despite its tremendous potential, 4D printing is still a nascent technology facing several challenges. The development of reliable, cost-effective smart materials and the optimization of printing techniques are some of the key hurdles. Additionally, as with any emerging technology, standardization and scalability will be crucial for its widespread adoption.

As research and development in this field continue, we can expect to witness groundbreaking advancements in 4D printing technology. The integration of advanced artificial intelligence algorithms and machine learning could enable objects to dynamically respond and adapt to complex and unpredictable situations.

4D Printing: The Future of Self-Adapting and Programmable Materials

The world of 3D printing has revolutionized manufacturing and design by enabling the creation of three-dimensional objects from digital models. However, scientists and engineers have taken the technology a step further by introducing 4D printing, an innovative approach that allows materials to adapt and transform over time. In this article, we will explore the concept of 4D printing, its applications, and its potential to reshape various industries. Join us on this exciting journey as we dive into the realm of self-adapting and programmable materials, where the past, present, and future meet to bring forth the next frontier of manufacturing.

Chapter 1: The Genesis of 4D Printing

|

| From digital design to dynamic reality - explore the intricate 4D printing process. 🛠️ #4DPrintingProcess #DesignToReality |

In this chapter, we will delve into the origins of 4D printing, highlighting its evolution from traditional 3D printing techniques. We'll also explore the key breakthroughs and scientific advancements that paved the way for this cutting-edge technology.

1.1 Understanding 3D Printing: A Brief Overview

To grasp the concept of 4D printing, it is crucial to first understand its predecessor, 3D printing. We'll provide an overview of 3D printing, its principles, and its widespread applications across various industries.

1.2 Emergence of 4D Printing: From 3D to 4D

The inception of 4D printing can be attributed to key innovators who saw the potential of adding a fourth dimension to traditional 3D-printed objects. We'll discuss how the addition of time as a dimension unlocks remarkable possibilities in material behavior.

Chapter 2: The Science Behind 4D Printing

|

| Envisioning a future where 4D printing reshapes industries and paves the way for innovative solutions. 🔮 #Innovative4DFuture #TechRevolution |

In this chapter, we'll dive into the scientific principles underpinning 4D printing, exploring the materials, mechanisms, and processes that enable objects to transform and adapt autonomously.

2.1 Shape-Memory Polymers: Unraveling the Secret

Shape-memory polymers play a pivotal role in 4D printing. We'll shed light on their unique characteristics and how they facilitate self-adapting behavior in printed objects.

2.2 Stimuli-Responsive Materials: The Catalyst for Transformation

Stimuli-responsive materials, also known as smart materials, react to external stimuli such as heat, light, or moisture, triggering a change in their properties. We'll explore the different types of stimuli-responsive materials and their role in programmable 4D printing.

2.3 The Printing Process: From Blueprint to Dynamic Reality

Understanding the 4D printing process is essential to grasp how these innovative materials are brought to life. We'll break down the steps involved in 4D printing, from design to the final transformation.

Chapter 3: Applications of 4D Printing

|

| Unveiling the magic of stimuli-responsive materials in programmable 4D printing. 🔮 #StimuliResponsive #4DPrint |

This chapter will focus on the practical applications of 4D printing across various industries. From healthcare to aerospace, 4D printing has the potential to revolutionize the way we design, manufacture, and interact with objects.

3.1 Healthcare: Advancements in Bioprinting and Medical Devices

The medical field stands to benefit significantly from 4D printing. We'll explore how it can enhance the creation of patient-specific medical devices, tissue engineering, and drug delivery systems.

3.2 Construction and Architecture: Building Smarter Structures

In this section, we'll discuss how 4D printing can revolutionize the construction industry by introducing dynamic and adaptive architectural designs.

3.3 Aerospace and Robotics: Self-Transforming Components

Aerospace engineers are increasingly exploring the integration of 4D-printed components in aircraft and spacecraft. We'll explore the potential impact of self-transforming parts on performance and maintenance.

Chapter 4: Challenges and Future Prospects

|

| Envisioning a future where 4D printing reshapes industries and paves the way for innovative solutions. 🔮 #Innovative4DFuture #TechRevolution |

While 4D printing holds immense promise, it also faces several challenges. In this chapter, we'll discuss the obstacles that researchers and manufacturers must overcome to unlock the full potential of this technology. Additionally, we'll envision the future of 4D printing and its role in reshaping the manufacturing landscape.

4.1 Material Limitations and Scalability

As with any emerging technology, 4D printing faces material limitations that affect its viability for mass production. We'll explore ongoing research and potential solutions to address these challenges.

4.2 Design Complexity and Software Innovations

Designing 4D-printed objects requires sophisticated software tools and expertise. We'll discuss the current state of design complexity and the need for user-friendly software to democratize 4D printing.

4.3 Environmental Impact and Sustainability

With the increasing focus on sustainability, we'll examine the environmental implications of 4D printing and its potential to reduce waste and energy consumption compared to traditional manufacturing methods.

4.4 The Future of 4D Printing: A Glimpse Ahead

In this final section, we'll paint a vision of the future of 4D printing and its transformative impact on industries, society, and everyday life.

|

| A glimpse into the healthcare domain, where 4D printing is revolutionizing bioprinting techniques and paving the way for personalized medical devices and tissue engineering. |

Conclusion

As we conclude our journey into the world of 4D printing, we can appreciate the immense potential of this technology to revolutionize manufacturing, healthcare, architecture, and beyond. With ongoing research, innovation, and collaboration, 4D printing is poised to unlock new possibilities, ushering in an era of self-adapting and programmable materials that will shape the future of our world. Embrace this paradigm shift and join the revolution of 4D printing!

4D printing is an exciting frontier that has the potential to revolutionize various industries by enabling self-adapting and programmable materials. By harnessing the power of smart materials and time as an additional dimension, engineers and researchers can unlock new possibilities in manufacturing, medicine, aerospace, and more. As this technology evolves, the world can look forward to a future where objects are no longer static but instead adapt and transform, catering to our ever-changing needs and challenges.

.gif)

0 Comments

Please do not enter spam links in the comment box.